This guide will show you how to use a Hashtek heat exchanger for cooling water during ice water extraction. The primary purpose of this is to reduce ice consumption, or possibly eliminate the use of ice all together. We know that yields are not impacted via iceless washing, as many of our customers have moved to filling their collection vessels with ice during continous recirculation (instead of filling the agitation tank with ice) . Using a heat exchanger can allow you to eliminate ice all together. Thus removing a potential source of contamination in your process and giving you complete control over your water chemistry.

Items Needed:

- A-Series setup for Continous Recirculation

- Neoprene Jackets for your collection and agitation tank

- Propylene Glycol (mix at 60/40 Glycol:Water)

- Outlet splitter

- Allows your glycol recirculation pump to only be on when the recirculation pump is on, prevent possibility of freezing within the heat exchanger. Thus glycol only flows when water flows.

- Chiller

- Cost Effective:

- Commercial:

- 3/8″ Silicone Tubing

- Hose Clamps

- 3/4″ Pipe Insulation

How it Works

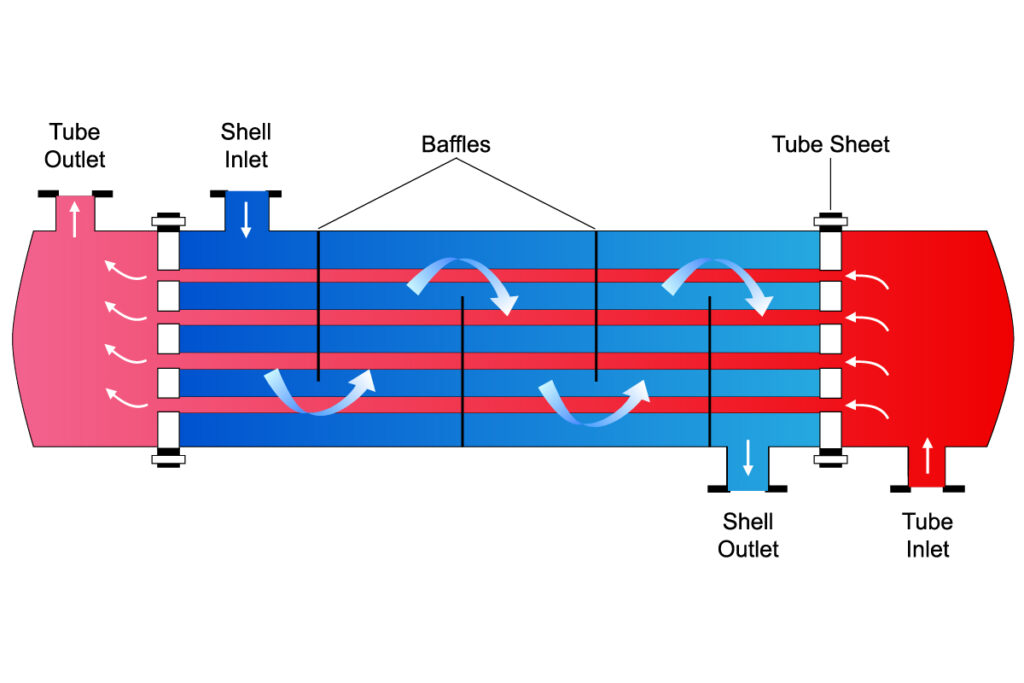

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact.

Hashtek Heat exchangers are built from polished 304 stainless and are designed for easy cleaning (when compared with brazed plate heat exchangers).

Installation

The chiller will be a large heat source, and should be placed outside of your hash lab. Either in another room or ideally outside. You will need to run two lines from you chiller to your heat exchanger. If using a Penguin glycol chiller (which requires an external pump) the setup should be as follows:

Penguin Chiller – > Short 3/8″ Insulated Tubing run -> Cast Iron Pump -> Long 3/8″ insulated run to Hash Lab -> Heat Exchanger -> Long run back to chiller

The cast iron pump that works well at cold temperatures is not particularly good at self priming. One of the biggest challenges is getting glycol to your pump and purging the initial air bubble from the system. Once all your tubing is connected, fill the glycol bath with glycol and turn the pump on. You may need to use your mouth to create suction on the return line to get the glycol going.

If you purchase a more commercial standalone recirculating chiller the pump will typically be included. The main problem with lab chillers is they are not designed to sit outside. The best chiller is a rooftop/outdoor installed chillers such as these penguin commercial glycol chillers.

Glycol Temperature for Ice Water Extraction

In our experience the preferred glycol set temperature is 28-30F. The glycol set temperature is the temperature that chiller will work to maintain in the glycol bath. When the glycol bath temp matches the set temp the compressor will turn off.

Setting the glycol set temp to 28-30F will prevent thin layers of ice from forming inside of your heat exchanger. If you try to use glycol temp colder than 28F you risk a thin layer of ice forming on the metal heat exchange point. The ice will act as an insulator reducing your efficiency, having the opposite effect you would expect.

Penguin chillers come with a built in temp controller and commercial/scientific chillers can have even more options. Some recirculating glycol chillers even have heating options which can be used to heat cleaning solution during a clean in place process.

Control of Glycol Flow

- Outlet splitter – Allows your glycol recirculation pump to only be on when the recirculation pump is on, prevent possibility of freezing within the heat exchanger. Thus glycol only flows when water flows. Simply plug the splitter into the recirculation pump outlet on your A-series. Plug the recirculation pump into one outlet and your glycol pump into the other.

- Inkbird Temp Controller – Allows you to leave water pre chilling overnight without risking the tank or lines freezing on you. Simply plug this into the outlet splitter and plug the glycol pump into the “cooling” outlet on the Inkbird temp controller. Set the temp on the Inkbird to ~32F.

Chiller Sizing

One of the most cost effective options on the market is the Penguin line of chillers. For more industrial options please contact us. Water may be cooled using either a jacketed tank (such as the Hashtek Cold Water Tank) or using the Hashtek Heat Exchanger.

| Penguin Chiller Size | BTU/hr @ 28F |

| 1/2 HP | 2,850 |

| 1 HP | 5,000 |

| 2 HP | 10,000 |

| 3.5 HP | 16,250 |

| 2 ton | 12,000 |

| 5 ton | 30,000 |

Cleaning

Hashtek designed a tube and shell style heat exchanger rather than brazed plate to facilitate easier cleaning. Because these are intended to recirculate process water the ability to properly clean and sanitize the heat exchanger is essential.

Clean in place processes are recommended for the heat exchanger. Simply recirculate a cleaning solution through the full system. Hot water and diluted isopropyl alcohol are common, as are cleaners such as oxy-clean. Flush with hot water and allow to air dry between use.