In our recent tek post we showed how a vacuum chamber can be used to speed dry hash in 1 hour making a caviar style product that could take 10-14+ days to dry using traditional air drying methods.

The material was not particularly high quality but it served well for the experiment. We then freeze dried the same wet hash as a comparison. My personal experience dabbing them was that the speed dry actually tasted better. We were interested in the differences on a molecular level so we sent samples of both off to HighNorth Labs for testing.

See below for a summary of the results for both drying methods:

| Compound (wt%) | Speed Dry | Freeze Dry |

| THC-A | 67.8024 | 65.1640 |

| D9-THC | 2.8712 | 3.2969 |

| Trans-caryophyllene | 2.5290 | 2.5381 |

| Farnesene | 1.7603 | 1.7595 |

| Alpha-Humulene | 0.9368 | 0.9359 |

| (R (+)-Limonene | 0.8364 | 1.1429 |

| Linalool | 0.4648 | 0.4930 |

| Alpha-Bisabolol | 0.3702 | 0.3584 |

| Beta-Pinene | 0.1233 | 0.1380 |

| Alpha-Terpineol | 0.1209 | 0.1207 |

| (R-Endo-(+)-fenchyl alcohol | 0.1039 | 0.1033 |

| Alpha Pinene | 0.0922 | 0.1045 |

| Caryophyllene Oxide | 0.0814 | 0.0741 |

| Farnesol | 0.0512 | 0.0500 |

| Beta-Myrcene | 0.0441 | 0.0581 |

| Camphene | 0.0275 | 0.0301 |

THC-A The freeze-dried hash displays a lower concentration of THC-A (65.1640 wt%) compared to the speed-dried hash (67.8024 wt%).

D9-THC: The freeze-dried sample shows a slightly higher concentration (3.2969 wt%) than the speed-dried one (2.8712 wt%).

Terpene Profile: Most of the terpenes listed show similar weight percentages in both methods. However, some terpenes like (R)-(+)-Limonene and Linalool are present at higher concentrations in the freeze-dried sample (1.1429 wt% and 0.4930 wt%, respectively) compared to the speed-dried sample (0.8364 wt% and 0.4648 wt%, respectively).

In summary, the analysis of the two drying methods indicates that both are effective in preserving the cannabinoids and terpenes in hash, with the freeze-drying method potentially retaining volatile terpenes more effectively. However, in terms of the THC-A to D9-THC conversion, both methods perform similarly, maintaining a consistent ratio that indicates a stable conversion process regardless of the drying technique. This suggests that producers can choose between speed-drying and freeze-drying based on operational preferences without significant concern for the cannabinoid ratios.

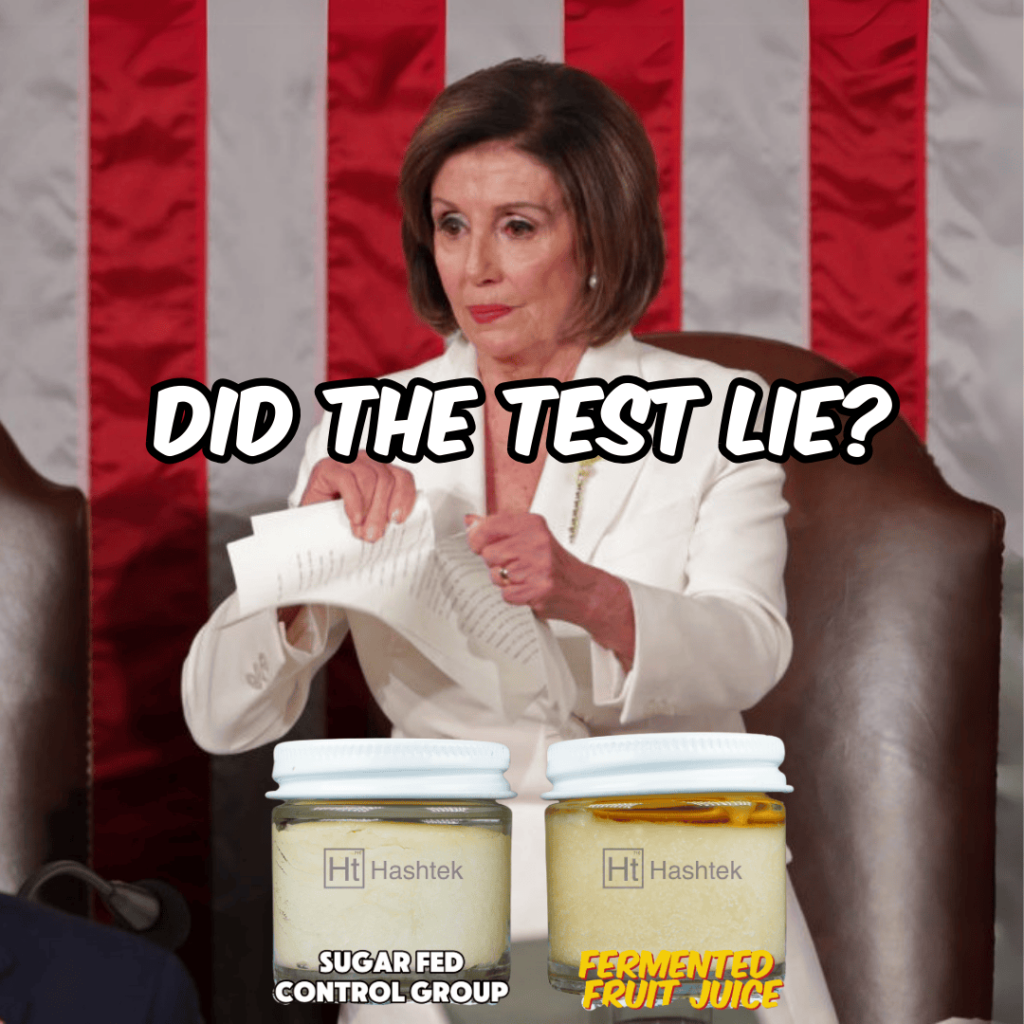

The samples are visually quite different, we believe further testing is required to explain these differences. Oxidation appears to be greater on the speed dry sample and moisture appears to be higher. Moisture tests should be completed next as unfortunately we did not have enough material this time around.

The sample on the left is the freeze dried one and the sample on the right is speed dried.

Speed Dry Full COA

high_north_coa_00453219-SPEED-DRY-rd-1

Freeze Dry Full COA

high_north_coa_00453218-FREEZE-DRY-rd-1