The hash rosin community is continually innovating, seeking methods to refine their craft and enhance the overall experience of their products. While the pursuit of purity is a common theme, the use of a centrifuge in hash rosin production has introduced a new realm of possibilities. This blog post will explore two primary applications of a centrifuge in hash rosin processing: Decarboxylation of THCA separate from terpene fraction, and a more efficient mechanical separation method compared to traditional cold pressing, particularly for products like THCA diamonds covered in sauce.

Section 1: Start with Hash Rosin

Hash rosin is known for its solvent-free purity, encapsulating the cannabis plant’s full array of cannabinoids and terpenes. The production journey begins with ice water extraction to create bubble hash, which is then transformed into hash rosin through the application of heat and pressure. This method yields a potent and aromatic concentrate that is highly valued in the cannabis community. The drive for innovation in this space continues, with the centrifuge emerging as a potential new tool in enhancing the versatility and efficiency of hash rosin production.

Section 2: Proposed Centrifuge Applications in Hash Rosin Processing

1) Decarboxylation of THCA separate from terpene fraction.

A key function of the centrifuge in hash rosin processing is its capacity to separate the components based on density. It’s important to clarify that the centrifuge is not used for the decarboxylation process itself; rather, it isolates the THCA and other components based on density. The separated THCA can then be decarboxylated externally to convert it into psychoactive THC. This separation is crucial as it allows the terpene fraction to remain unaltered by heat during the decarboxylation process, preserving its aromatic integrity. Thus, the centrifuge can serve as a means to refine and prepare the THCA for decarboxylation, while safeguarding the delicate terpenes from any thermal degradation.

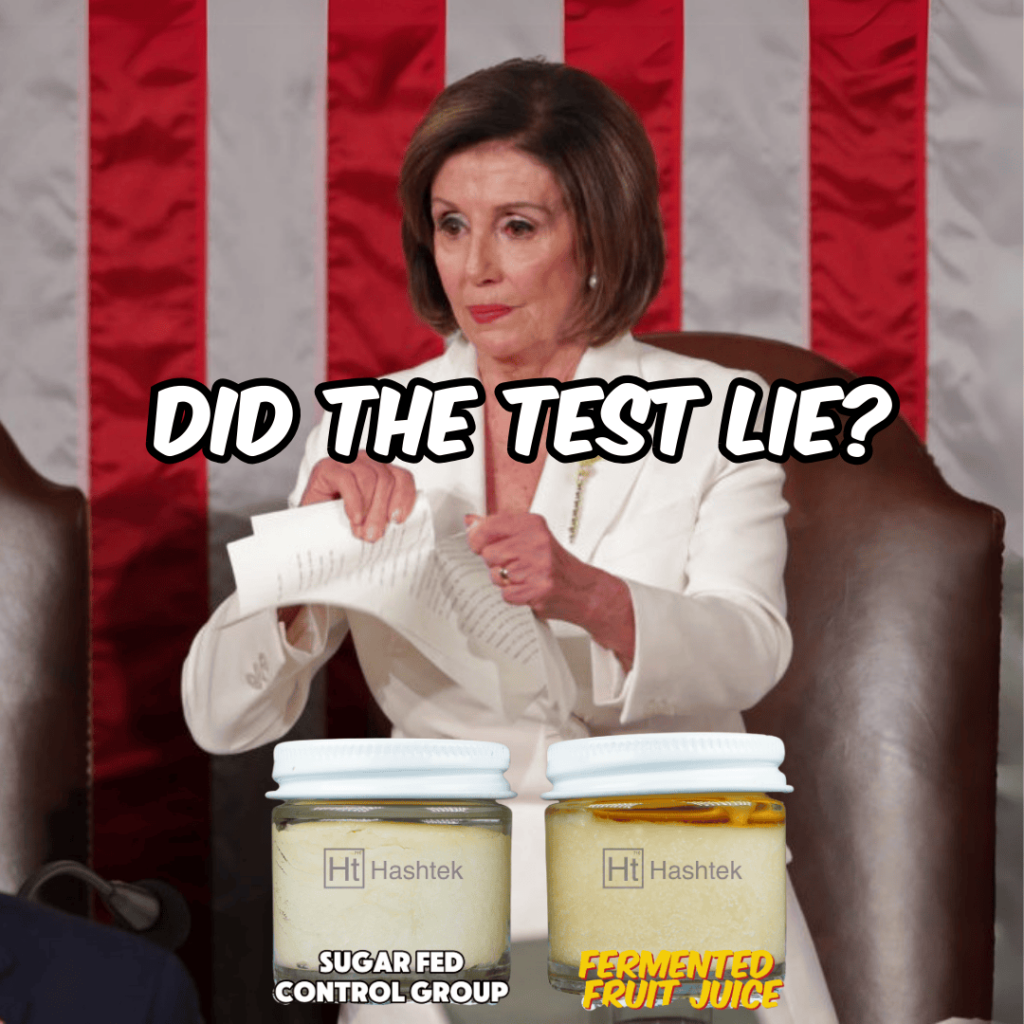

The image above shows traditional rosin decarb where the all the terpenes and cannabinoids are present during the decarboxylation reaction.

2) Mechanical Separation Efficiency:

Another significant application is the centrifuge’s role in mechanical separation. Traditional cold pressing can be labor-intensive and less efficient, for example when producing THCA molds covered in sauce at scale. The centrifuge offers a more streamlined approach, separating the crystalline THCA from the terpene-rich sauce with precision and ease. This method not only saves time but also minimizes the loss of product, leading to a more sustainable production process.

The images above depict THCA separated from the terpene fraction. Photos provided by Justin from LowKeyAlchemy.

The images above show THCA/Sauce preparations made by SimpsonSolventless.

Section 3: The Centrifuge Process for Hash Rosin

Choosing Cold Cured Over Fresh Press: While fresh press can be used in the centrifuge, Justin Massie from LowkeyAlchemy has found through experimentation that cold cured rosin is preferable. The cold cure process allows for the crystalline structure to mature, which in turn yields a more abundant terpene fraction when separated.

Loading the Centrifuge: Distribute the cold cured rosin evenly within the centrifuge’s filter basket container to ensure a balanced and effective spin. At a small scale a 25u press bag and tube or jar may be used. At scale purpose built containers with filter mesh baskets or a filter layer between two compartments makes more sense. As with ice water extraction do not overload the vessel and start low while you get familiar with the limits of your system.

Metal mesh baskets are a more sanitary and reliable option for production at scale, but for R&D and home use a simple 25u mesh bag with the cold cure inserted in it and the bag suspended by flipping it over the jar and putting the lid on will suffice. Photo credit: LowKeyAlchemy.

Contact @hashcru if you are interested in his custom made containers for Baxter brand cetrifuges.

Terpene Recovery via Heat: After centrifugation, you can apply light heat to the metal container to aid in the recovery of the terpene layer. Inverting the container allows the terpenes to drip out, minimizing container loss.

In the video above Justin Massie shows off terpene fractions of various consistencies that have been isolated using a centrifuge with rosin as the starting material.

Collecting the Crystalline THCA: After the centrifugation process, the crystalline THC should be compacted within the filter basket or bag as a compressed puck, distinctly separated from the liquid terpene layer that collects at the bottom of the vessel outside of the filter basket. This method of centrifuge refinement, guided by empirical findings, allows producers to enhance the terpene fraction in their hash rosin and efficiently isolate the crystalline THCA structures.

The photo below shows the THCA fraction being removed from a nylon 25u filter bag that was placed into a jar with the lid being used to secure the mesh in place. The sauce was spun out and ended up in the bottom of the jar.

Section 4: Tips for Optimizing the Centrifuge Technique

Precision in Parameters: For mechanical separation, focus on the optimal speed and time to cleanly separate the THCA from the sauce. You do not want the sample to get hot enough to begin decarboxylating in the centrifuge, but it should be warm enough to allow the sauce components to flow through the filter. The force exerted at the filter screen is proportional to the radius of the rotor and the speed of the centrifuge. Choose the correct centrifuge for the process.

Balance and Calibration: Properly balance the centrifuge tubes to maintain the integrity of the machine and the safety of the process. An unbalanced centrifuge can be extremely dangerous.

Experimentation for Perfection: Each strain and batch may require slight adjustments. Don’t hesitate to experiment within safe parameters to achieve the best results.

Section 5: Understanding Oxidation in Centrifuge Refinement vs. Traditional Mechanical Separation

Understanding the nuances of oxidation in hash rosin refinement is crucial, and Justin Massie of LowkeyAlchemy provides valuable insights into this aspect. “An important aspect I want people to understand here is the difference between oxidation here and oxidation in a mechanical separation,” Massie explains. In the centrifuge process, the intense G forces ensure that only the topmost layer of the rosin is exposed to oxygen, limiting the interaction to the same few oxygen molecules. This is a stark contrast to traditional mechanical separation, where the terpenes are spread in a thin, wide layer across parchment, leaving them vulnerable to numerous oxygen molecules and, consequently, a higher rate of oxidation.

Massie further illuminates the benefits of the centrifuge method in mitigating oxidation, “This process can be done in sealed containers and backfilled with inert gases, bringing the problem of oxidation in post processes to a screeching halt.” By employing sealed containers and introducing inert gases, producers can virtually eliminate the risk of oxidation that typically occurs during and after mechanical separation. This advanced approach not only preserves the terpene profile and potency of the hash rosin but also ensures a fresher, more vibrant end product for the consumer. Through Massie’s expertise, it becomes clear that the centrifuge refinement process represents a significant leap forward in maintaining the quality and longevity of hash rosin concentrates.

Conclusion:

The introduction of the centrifuge into hash rosin processing has opened up new avenues for producers to refine their products. Whether it’s for the separation of THCA for decarboxylation or for a more efficient mechanical separation, the centrifuge stands as a testament to the innovative spirit of the cannabis community. By understanding these applications and optimizing the technique, producers can create hash rosin products that stand out in quality and efficiency. Embrace the technology, and let the centrifuge revolutionize your hash rosin production.

Background

Running rosin through a centrifuge is something we have wanted to do for some time. We finally got the opportunity at an Evolved Extraction seminar taught by MurphyMurri at YellowStone Extraction in Guelph. The seminar was focused on teaching how to cold crash THCA out of butane, a solvent based processes that goes outside solventless extraction methods. But they were nice enough to allow us to run some cold cure rosin through their centrifuge! These are the results from the initial experiment that encouraged us to take a deep dive into the topic of running rosin through a centrifuge.

2 Responses

Great job!

This is incredibly eye opening.