In our ongoing Hashmaker Q&A Series on the blog, we had the opportunity to interview Hana from Mission Hill Melts not too long ago. Now, we’re returning to engage in a conversation with the founder and the other half of the team, Adam.

Adam started MHM out of a small apartment in Boston back in 2015 with the goal to supply New England with hand-made, high-quality solventless concentrates. Today, the dabbing duo releases products on the Rhode Island and Maine medical markets, offers solventless production consulting, and hosts a variety of community events.

They’ve built their brand over the years by working with hand-selected, high-end yet small-batch farms such as Aloha Apothecary and ELM Cultivation to process some seriously stunning rosin and full-melt hash. Today Adam is here to share his insights into the benefits of toll processing and how this model has helped to achieve a faster ROI on their Hashtek 50-A Series.

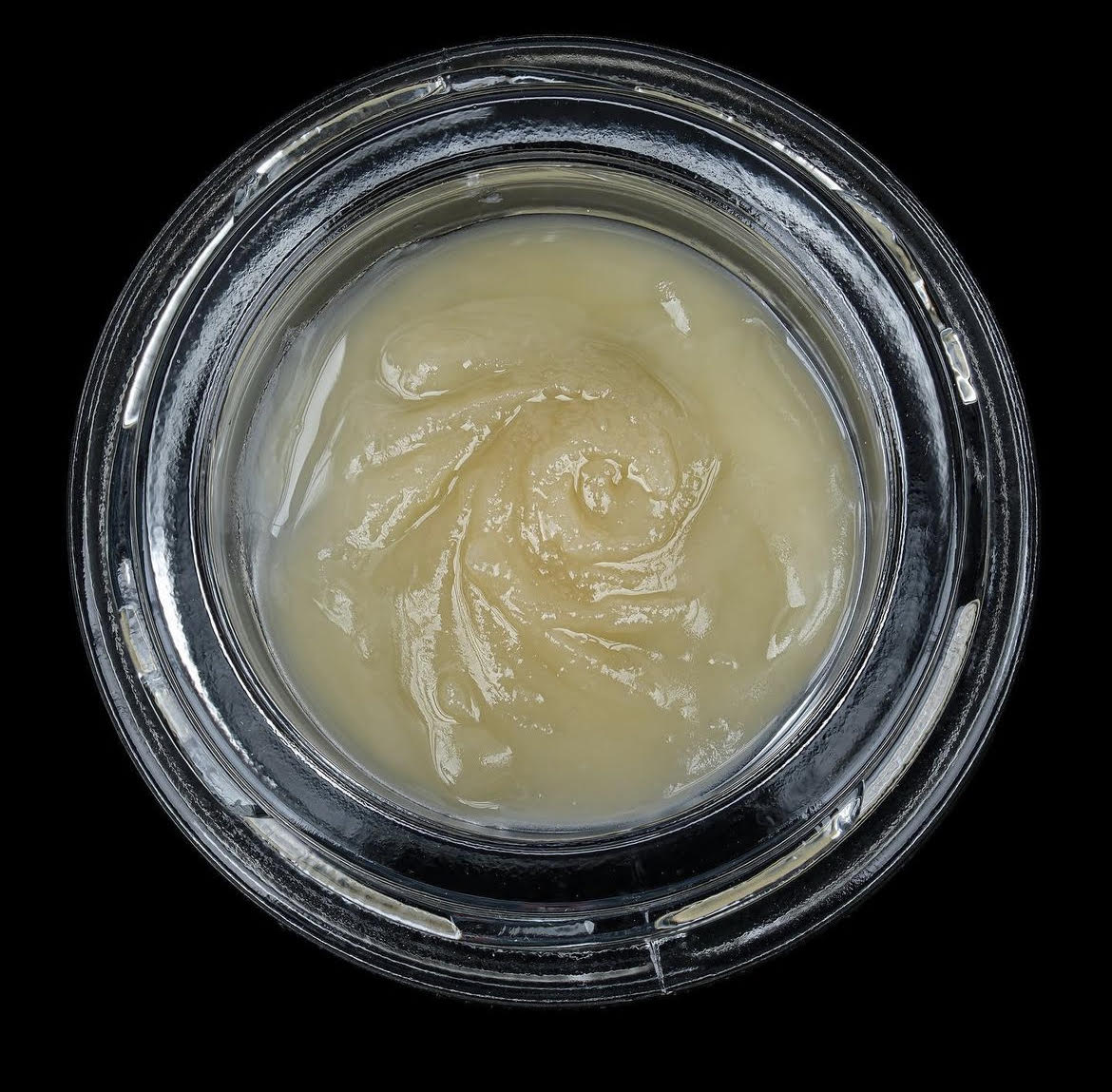

Photo by Mark Archer

What are some of the different types of processing you can do as a solventless producer?

While we have done single-source in the past, we don’t currently have our own cultivation facility. So we’re strictly doing processing, and in our world, there are basically two types of processing commission work. You can either do splits, where you end up with a percentage of the finished product after production. It’s on you to package, market, and sell that product.

Or you could do flat rate processing, or toll processing, where you’re just getting paid to process and then give all the finished product back. It’s not on you to sell it. With toll processing, we charge per amount of fresh frozen material we process which is washed, squished, and delivered back in cold cure rosin form.

In what cases would you typically do toll processing vs splits?

On our split side will usually offer up some sort of packaging, so that’s if you want your runs packaged up under our branding. That obviously has to have a certain level of quality, so that works really nicely when you know your farmers and you know the strains they’re working with, and you’re confident that they’ll hit over a certain number. For us, pretty much anything over 3% is workable with splits. At the end of the day, if you know the growers, the quality, and the yields, percentage splits are really nice.

If you’re working with new people, or you’re working through pheno hunts and not sure what the yields will be, or maybe it’s just a buddy who needs you to run some stuff for them, that’s usually when we do the flat rate processing.

It really just depends on what your own situation is. For us at Mission Hill Melts, we’re doing things on a small-batch scale so we aren’t producing a super large quantity of concentrates. We like to be able to do the splits when we can because that gives us more product to move instead of just getting paid out. We want to be able to serve our patients and our caregivers with quality product. But cash on hand is key when you have bills to pay – to be able to hand somebody a run and get a payment right back after is always nice.

Is there any seasonality to your processing schedule?

It’s seasonal for sure. We’re in a medical state and we’ve got a decent outdoor climate, so people grow nice sun-grown flower out here. October and November, after the outdoor crop drops, is easily our busiest time. We processed ~200,000 grams in a month and a half during the peak outdoor season last year. At that point, we’re shuffling freezer space as quickly as we could empty stuff, we would have people who would want to drop more off so they can harvest more. Having the Hashtek made it so that we could just be more efficient for our growers, who were getting their runs back in record time pretty much.

And then the wintertime kind of slows down and you just sort of work through what you processed during the fall. You got your homies, you’ve got a couple of indoor things going. That’s when it also becomes really nice to have the machine and do a balance between flat rates and splits. The good thing about offering both is that in case things do slow down, you still have some stuff coming in just from the flat processing.

When you are doing splits and associating a grower’s name and material with your brand, how do you make sure the quality is there?

We usually do the flat processing the first time we work with somebody new as an insurance policy, just because we don’t know what it’s going to be like. And then if that first run comes out well, we’ll start a relationship doing splits. If it’s somebody working with genetics we like or has a cut from a buddy, or we’ve seen their material processed by someone else and know the quality is there, that’s when we’re more inclined to go for the splits off the bat.

Photo by Mark Archer

Do you have any tips for managing those relationships when you’re doing toll processing or splits?

We have a list we send out to people that gives an overview of all the important things like our processing rates, how we expect fresh frozen to be harvested, to be taken care of, and how we expect transport to go. So we try to have a pretty good open dialogue with people before we even wash. It works out better for everyone, especially when you’re processing other people’s stuff. It’s like the better you can do, it’s a win for everybody. So having good communication and setting clear expectations from the start is one of my tips for sure.

We also try to find farmers who are smaller scale and focused on quality like we are. A lot of these people are just straight growers and haven’t had as much experience with solventless, or just don’t have the space or the time to wash themselves. We try to work with them to get their genetics in a place that works for both of us with flower and hash. Building long-term relationships with benefits for everyone. Growing is a full-time job, and it’s kind of nice for our growers to be able to go through their process, harvest, and then hand things off to us. Then they have a nice week or two to chill, reset their rooms, and not have to go from that hectic harvest and break down and clean up right into fresh frozen processing. It just takes a little bit of pressure off our growers.

You should let people do what they do well and love, and we really love making hash and squishing rosin. It’s what we’ve been doing for years. We’ve grown from time to time, and we will be again soon, but we’ve always been hash makers first. You’ve got to have that passion to really be successful with it.

How have you been able to achieve a faster ROI on your Hashtek machine through the toll processing and splits?

I feel like if you have the machine, business almost just comes to you. For me, before when I was hand washing, my physical well-being was pretty much the limiting factor on how much I could produce. My shoulder started getting really worn out towards the end of my hand-washing days and I could only do like, maybe two washes a week. Even when I had an assistant helping me out, you’re still limited by their energy level and their availability.

The Hashtek has never taken a sick day. Something that I realized was that our energy and our washing from the first wash of the day compared to the last wash of the day were obviously not the same. Like we’re all just so tired by that last wash. The machine is more consistent in that sense, doing exactly the same thing every time. It only took about 200 production washes for it to pay itself off compared to if I were to pay a human being to help me hand wash, and we’re typically running 4-6 washes per week. On top of that, I don’t have to hand stir so my physical well-being is better, and I can do other valuable things with my time while the machine is going.

Even if you do have a single source operation, offering toll processing or splits as a Hashtek user creates another income stream and helps you pay off the machine faster. Depending on what your harvest schedule is like, your machine is going to end up sitting unused. It’s better to be generating money with it than have it sitting there, so if you start working in some toll processing, you can maximize the investment in the machinery. We’re actually in the process of doing paperwork for our own cultivation site, but we’re still going to continue on with our toll processing. If we got the machine, we’re going to be using it to its max!

Alright, let’s recap things…

When to consider splits as a solventless producer

- You don’t have your own single-source garden

- You feel confident in the quality, genetics, and yields of the cultivator you’re working with

- You’re looking for additional high-quality product to supply your own patients or customers

- You’re looking to add more variety to your menu by offering flavors you don’t grow in-house

- You have the time and team resources to market and sell the product yourself

- You have processing equipment that is not being used to its fullest capacity

When to consider flat toll processing as a solventless producer

- You’re starting to work with a new cultivator, working through pheno hunts, or washing new genetics for the first time and are unsure of what the quality and yields will be

- You’re running material that would not meet your standards to be packaged under your own branding

- You have down time in between seasons or harvests

- You’re looking for immediate payment after processing

- You don’t have the time or team resources to market and sell the product yourself

- You have processing equipment that is not being used to its fullest capacity

Got more questions on processing as a craft solventless producer? Reach out to the Hashtek team anytime. And as always, happy hash making!