Hand rolling anything is an art. Not everyone can roll a perfect joint, but with practice, hand rolling your smoke can be a rewarding experience. Rolling hash can be more difficult than working with papers. Successfully sculpting a hash wrap can put you into a state of zen. The purpose of this guide is to give the reader the ability to press trichome heads, stalks, and possibly some additional cannabis plant matter into a hash sheet or hash wrap that can be used in place of rolling papers. The hash wrap can be filled with cannabis, more hash, or enjoyed without filling as a convenient way to consume hash. This guide is for the DIY person making wraps at home for personal consumption. If you are interested in producing wraps at scale, we can provide consulting and SOPs for mass production of hash wraps.

Understanding the hash you are working with is key to making a successful wrap that will burn easily without falling apart. Dry sift hash from dry, cured flower can be the easiest material to use to form wraps. Hash that is >1.5% terpene content might be difficult to keep stable, so hash that makes gooey, wet-looking rosin should be used for making rosin or consumed as full melt. High-quality hash can be mixed with lower-quality material; blending hash from different sources can make great wraps. Once you have mastered making wraps using dry sift, forming wraps with higher quality bubble hash will be easier.

Non-decarboxylated material is needed to make hash wraps; do not expose the hash to heat. Try to source fresh material that is less than one year old when possible. THCA is always a crystal and solid at room temperature; material that is high in THCA makes solid wraps. Delta 9 THC is always an oil at room temp and will not make a solid wrap. If you have access to lab testing, knowing the percentage of cannabinoids can be useful. The material I use has tested between 35-68% total cannabinoids. The 40% range seems to be the sweet spot to make solid wraps that burn successfully for novice wrap smokers. When I make higher testing wraps, it’s often difficult to burn them while passing around to a group of new hash wrap consumers. The higher quality wraps need special care, like rotating while burning to keep them from dropping and crashing. If a hash wrap comes apart while smoking, it is no big deal; you still have hash, just put it in a bowl and enjoy.

It is helpful to make a journal to record information about what works and make notes about what does not work for making a wrap. This is where you record observations about material quality, temps, pressures, time weights, etc. If you do not have access to lab analysis for cannabinoid and terpene content, record observations about the percentage of heads, stalks, and other plant matter in your material. Record observations such as how it behaves when dabbed as full melt. Use photos, a microscope, or a magnification lens to observe the hash quality.

For the purpose of this guide, I will be talking about using dry sift, loose hash made in a tumbler. Start by tumbling the material for only 2 minutes. Collect that material and try to make a wrap from the 2-minute collection. If the wrap is too melty or just pulls apart, you probably need some additional contaminants like trichome stalks or plant material, and you will need to run the tumbler for more time. As you increase the time, more plant contaminants come through the screen. If you have too much non-trichome plant contaminants in the hash, the wrap will not be stable. I typically do not use material that has been tumbled for more than 20 minutes total time. I have observed that some strains do not make good wraps. My hypothesis is the amount of silica in the cell walls affects the ability of the hash to form a stable sheet that will not melt. Successful hash wraps have been produced from high-quality clean hash with very few stalks and contaminants, greater than 95% heads. Other makers have reported 98-99% heads for their wraps. Wraps made from 90%+ heads will probably not appear to be full melt; the head sheath tends to be more robust and does not rupture easily.

Once you have collected enough hash to make some wraps, the next step is to determine the size wrap you want to make. I prefer five centimeters by six centimeters for making a wrap that’s similar in size to a standard joint. When I first started making wraps, I used more hash and made the wraps thicker; this made the wrap easier to roll. My first wraps were 2-4 grams per wrap. I now try to make the 5×6 cm wraps about 1.2g in total weight. When using 1.2 grams of hash, the sheet can be pressed very thin.

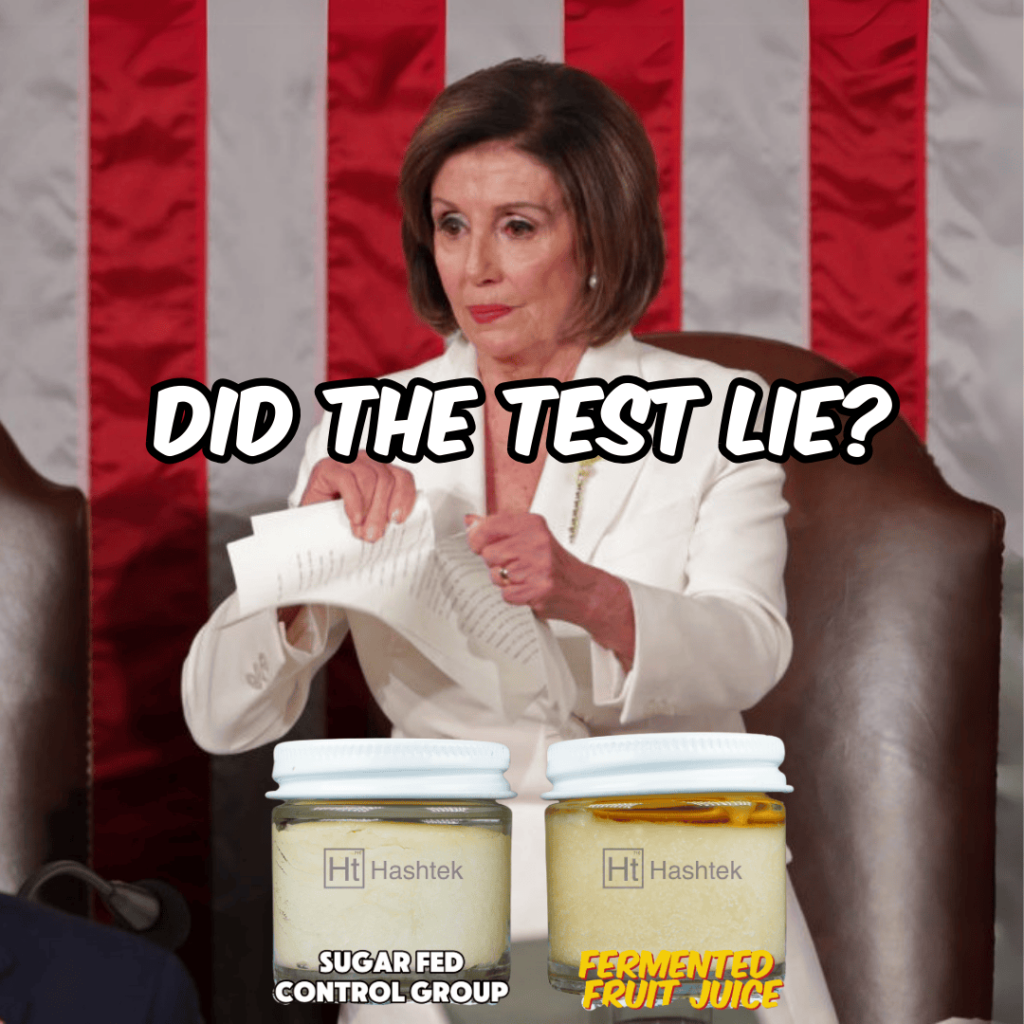

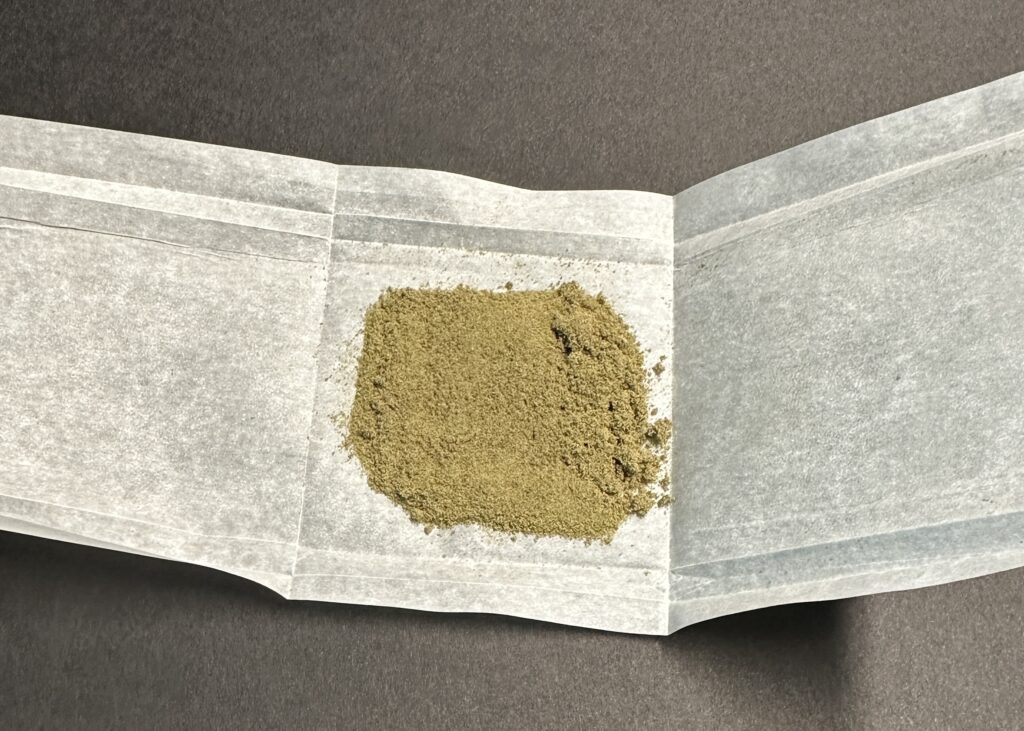

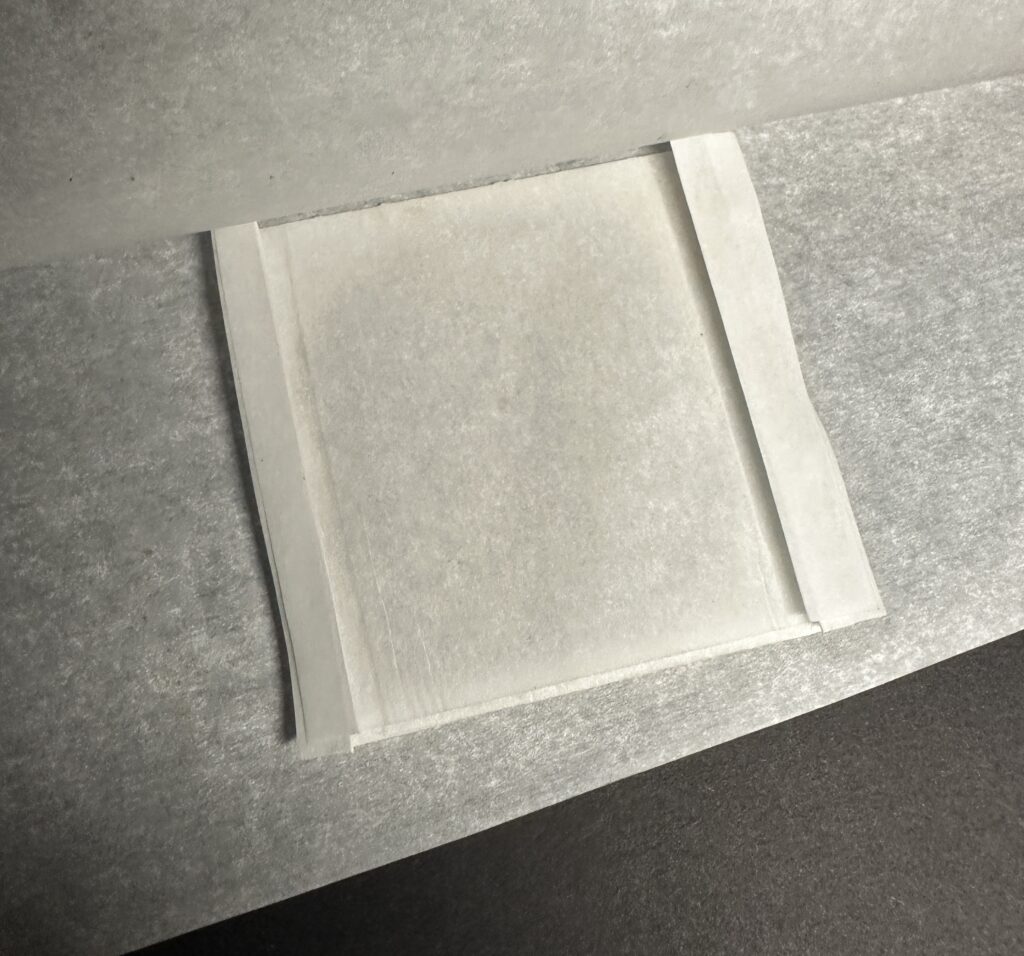

Use a piece of parchment paper and fold as shown below, with the center rectangle the size you want to make the wrap. If you do not fold the edge of the parchment all the way to the other edge, the thickness of the wrap will be inconsistent and uneven. The technique shown for folding the parchment paper makes raised rails on two sides of the pouch that reduce the chance the press will break the parchment and squeeze all the hash out the sides. Evenly distribute the hash in the parchment paper, trying to make it as uniform as possible prior to pressing.

Once the pouch is folded, hold it up to a light source and verify that the hash is evenly distributed in the pouch. You can tap or flick the pouch with your finger to distribute it.

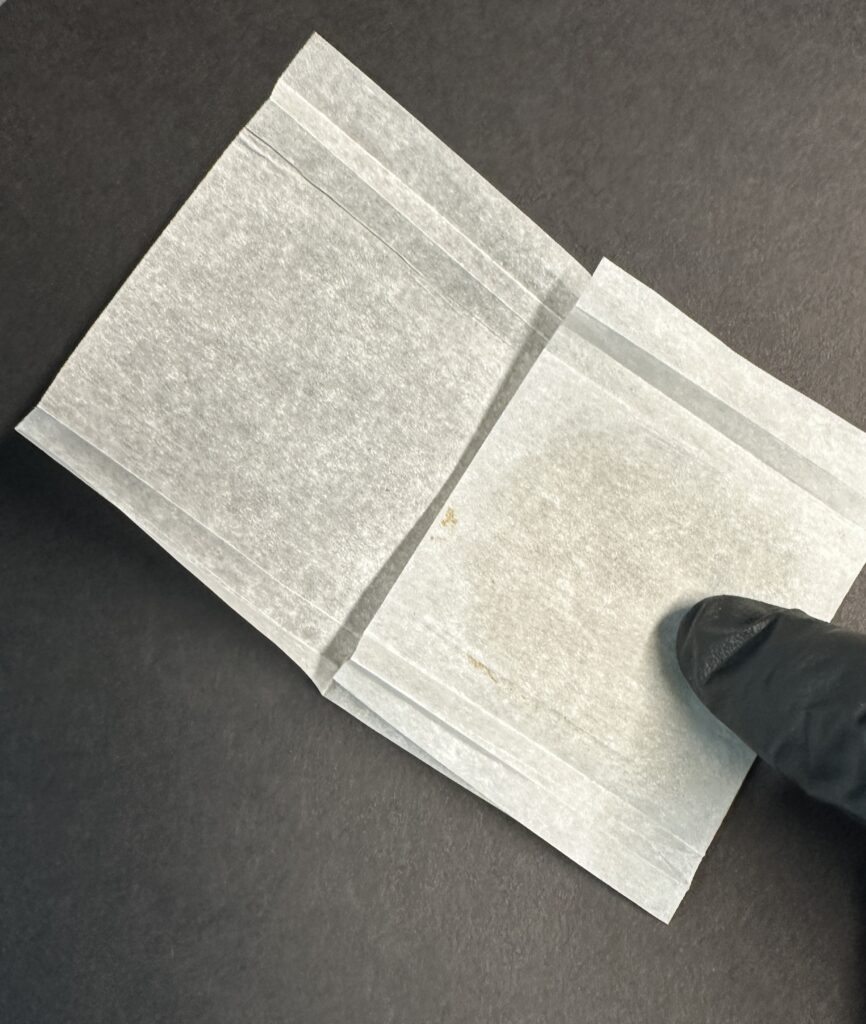

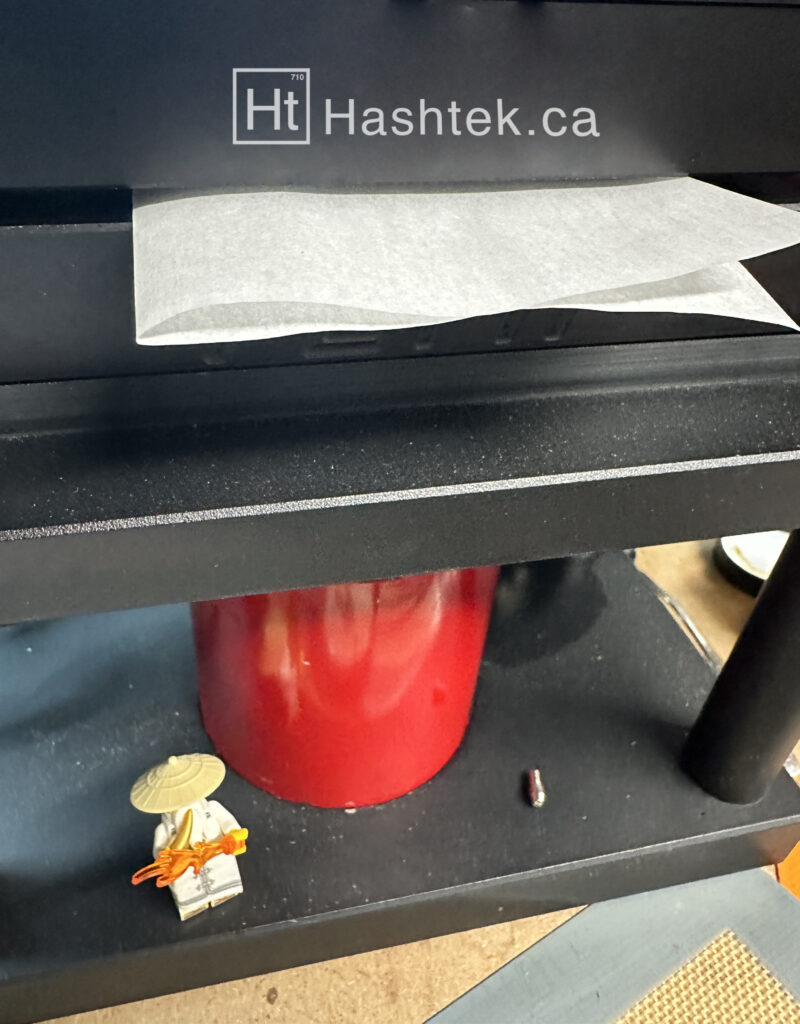

Place the folded pouch inside another piece of parchment folded once; this will keep your press plates clean from any hash that may squeeze out of the pouch.

The precise temperatures, pressure, or time for pressing will vary depending on the quality hash used. As the hash quality increases, the temperature and pressure required decrease. The opposite is true as the quality of the hash decreases; the pressure and temperatures increase. Since pressure readings between press manufacturers can differ from the pressure applied at the area being pressed, I will not give out any pressure gauge values. Instead, I will talk about the pressure applied to the material being pressed. I typically do not exceed 500 PSI on the actual material. If you know how to calculate that for your press, then you can use that pressure as a guide.

When using a rosin press to press dry sift, the suggested temperatures are between 48 and 77℃ (120-170F). If using a clothing iron, temperatures as high as the steam setting can be used. The relationship between quality of hash, temperature, and pressure is all interdependent. You can use lower temps with higher pressure and higher pressure with lower temps. The heat and pressure are used to break the sheath around the trichome heads and get the cannabinoids and terpenes to flow and ideally make a homogeneous, paper-thin piece of hash. If the material is heated too much, decarboxylation can occur and the wrap will not properly nucleate and solidify. Start pressing with a low temperature when working with new material and increase the temperature until you find the combination of temperature and pressure that works for your material.

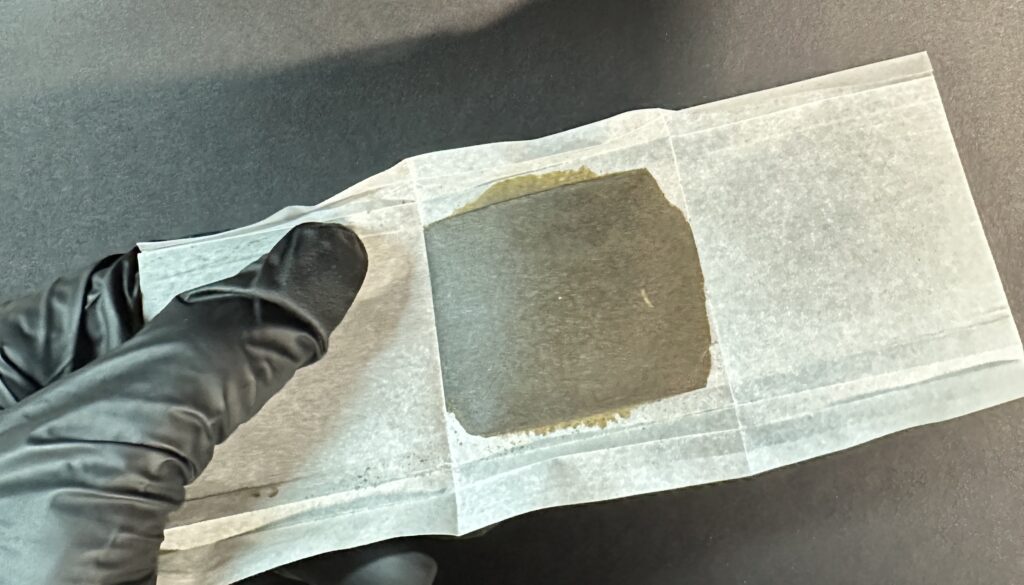

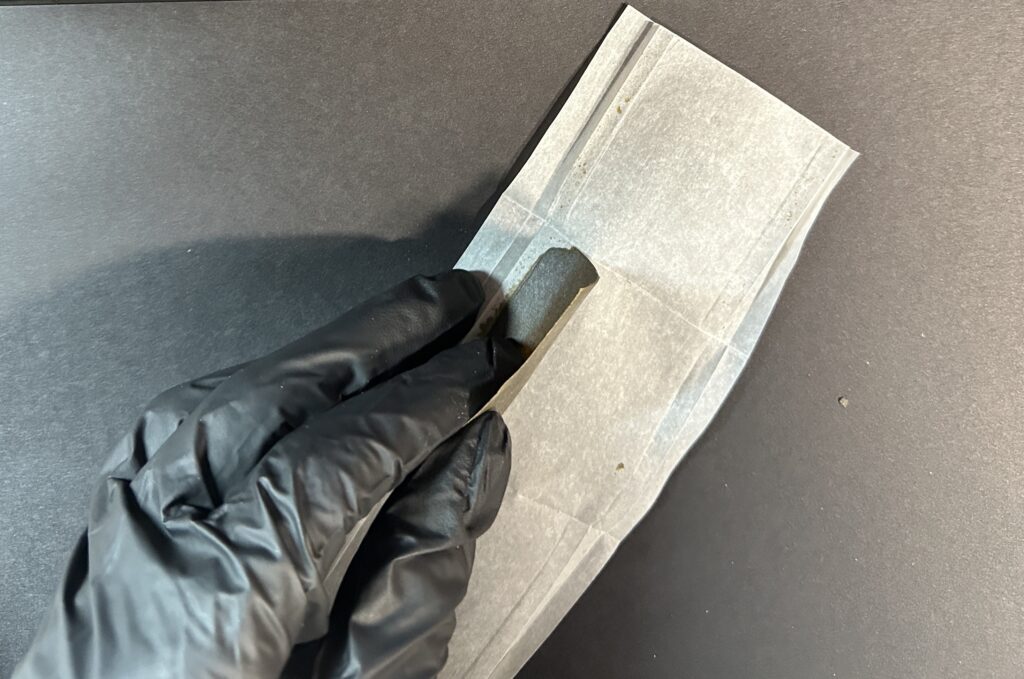

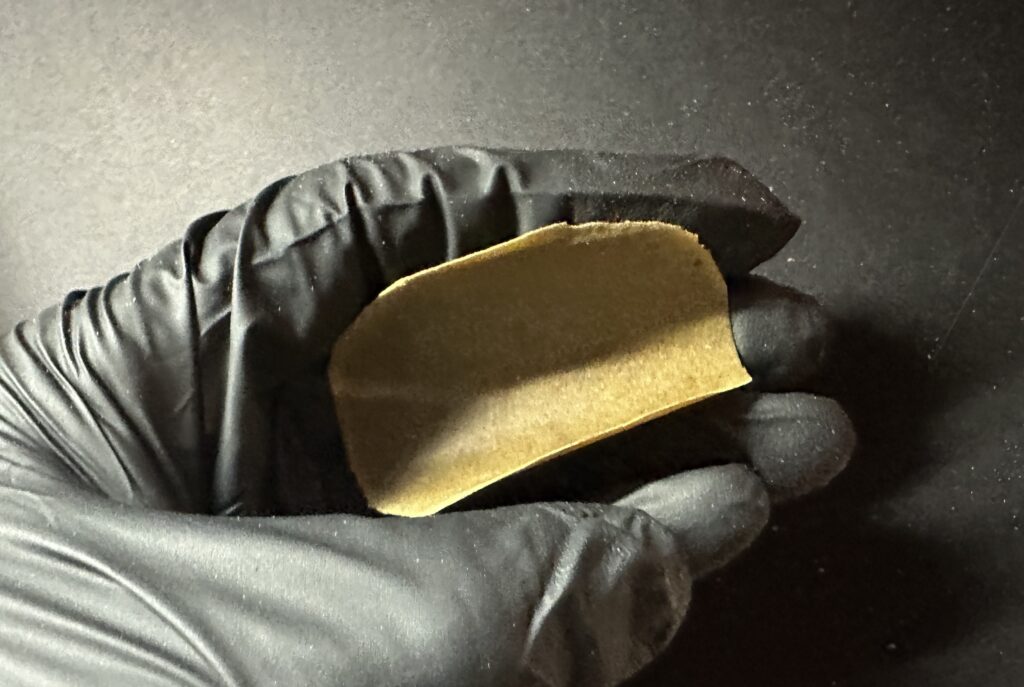

The folds on the edges of the pouch should prevent the press from pressing all the hash out of the parchment paper if it blows out on the folds. Apply pressure and then release the pressure immediately once you hit the pressure that works for your material. As soon as you remove the parchment pouch from the press, place it on a cold plate. Remove it from the cold plate once cooled and remove the hash sheet from the parchment. Use the warmth of your hand to heat the hash sheet to form a tube. People have several preferences for rolling, so I’ll leave that up to you to determine how to wrap your hash. You can easily hand roll the wrap as demonstrated in the following photos. You may need to use a tool to push inside the tube to get the seam to stick together, or you can use partially decarboxylated hash as a glue to stick the hash together. Any strain of hash will work for this purpose.

Once you have formed your wrap, you may need to cure it to form a stable wrap. If the wrap is melty and flexible, it can be cured until it forms a hard or stable shell. During the curing process, the cannabinoids in the hash that are solid at room temperature will nucleate. The optimal environmental conditions for curing are temperatures from 10-22℃ and humidity less than 50%. I have filled wraps prior to curing and post-curing. Depending on how I roll them, I sometimes find that filling them after curing makes a cleaner-looking wrap.

I have stored wraps for over 12 months in a nitrogen-filled sealed tube, and they have all burned down successfully. For long-term storage, I recommend storing them in an inert gas-sealed container, stored below zero degrees Celsius. If you do not have access to a freezer, any cool (<24℃) environment will work.

Once the wrap is ready to smoke, there are a few things to keep in mind. As the hash heats up, it will become soft; do not touch the hash once it is lit, hold the wrap at the glass tip. Do not tap the wrap to ash; allow the ash to fall off on its own. Sometimes you can burn an entire wrap and the ash will not fall off. Try to keep the wrap vertical as it is burning. This will prevent the wrap from drooping or sagging as it heats up. It’s easiest to keep the wrap vertical by hitting the wrap like a chillum. Enjoy!